Galvanized sheet suction fan |

|

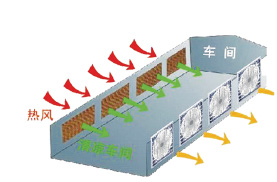

| Suction fan principle |

| Negative pressure exhaust fan exhausting air out the room pressure drop, indoor air thinned to form a negative pressure zone, the air pressure difference will be compensated because of the interior, creating an airflow into a canyon with. Practical applications, centralized suction fan mounted on the side of the plant, through specific engineering design, according to the need to design ventilation rate and wind speed, any fever, harmful gases, dust can quickly exhaust smoke shop, any problem can once poor ventilation sex completely resolved. You can shop by negative pressure exhaust fan exhaust fan from a few seconds to open and close doors and windows near the suction fan remains off, forcing air to flow into the air inlet side of the shop windows from compensation. Air lined up orderly inflow from the air inlet airflow workshop with the formation of the canyon. Negative pressure ventilation fan thorough, efficient, and ventilation rate can be as high as 99%. |

| Features |

Suction fan blades using 201 series stainless steel, with a large amount of wind, low noise, low energy consumption, long life, stable operation, appearance and other characteristics, easy maintenance, the provincial enchant belt trouble! Blinds closed automatically start up to dust, water effects, to hair, but also ventilation, greenhouse, plant cooling ventilation best choice.

The main structure:

Mainly by the fan blower, motor, frame, grille, cage, blinds and other components, motor-driven fan produces airflow, venetian blinds according to user needs with the type, the boot can automatically open blinds, shutters closed automatically shutdown to prevent dust from entering, but also avoid the impact of rain and snow and wind down.

Features:

Frame using advanced automatic processing, high precision; special thick zinc coating, anti-corrosive. High-strength aluminum alloy wheel hub, the new twisted metal forming blades; reasonable airfoil angle, can achieve maximum air flow; precision microcomputer aided manufacturing system allows the fan to maximize performance. 5 strict quality testing procedures: noise detection, vibration testing, performance testing concentric rotation, fan speed detection, machine efficiency testing; performance 380V three anti-special motor. Wind is set using the iron, glass and steel set of wind, a convenient set of ABS plastic air filter (three kinds) rear safety net disassembly; CAD optimization design.

Suction fan Scope:

A, suitable for high temperature or smell of the workshop:

Such as heat treatment plant, casting plant, plastics plant, aluminum factory, shoe, leather factory, electroplating plants, a variety of chemical plants.

B, applicable to labor-intensive enterprises:

Such as garment factory, various assembly shop, internet cafe.

C, ventilation and cooling greenhouse horticulture, aquaculture, livestock farms cool.

D, especially for applications that require cooling also requires a certain humidity locations. Such as tobacco warehouses, cotton, woolen mills, jute mill, weaving factories, chemical plants, Jingbian, knitting, etc.

E, suitable for warehousing and logistics. |

| |

|

A suction fan 1 hour workshop will 700m3 (approx 100m3 workshop) indoor and outdoor air exchange 44500m3 / h = 63.5 times, so that each location has a family room fan blowing straight results. And let the dust, moisture and more sultry plant becomes cool and comfortable. Suction fan is not installed only indoor cycle plant, inside and outside air exchange up less than 10 times. |

| Model |

Air volume(m3/h) |

Power |

Speed |

Voltage |

number of sheets |

Blade material |

Outer frame |

| HF-A1530 |

55800 |

1.5 |

440 |

380 |

6 |

Stainless steel |

Galvanized sheet |

| HF-A1380 |

44500 |

1.1 |

360 |

380 |

6 |

Stainless steel |

Galvanized sheet |

| HF-A1220 |

37000 |

0.75 |

360 |

380 |

6 |

Stainless steel |

Galvanized sheet |

| HF-A1100 |

37000 |

0.75 |

300 |

380 |

6 |

Stainless steel |

Galvanized sheet |

| HF-A900 |

30000 |

0.75 |

427 |

380 |

6 |

Stainless steel |

Galvanized sheet |

|

|

|